Fatigue 4.9 Crack Characteristics Road Free Download 2023

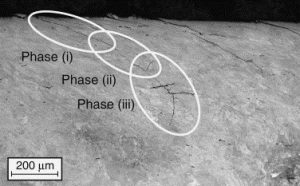

Fatigue Crack 2023 initiated in a gusset plate attachment set up the fatigue crack that propagated and allowed the air distributor pipe to break completely. So, Fatigue is commonly generating from surfaces of the component at surface irregularities or discontinuities either already in existence or have been produced by slip bands, grain boundaries, or second-phase particles (Obrtlik et al.

From Paris [2], the propagation of a crack follows the basic form of:

where C and N are material constants, and

where C and N are material constants, and

![]() da/dN is the crack growth in mm/cycle. So, The values of C and N can vary due to heat treatment and the condition of material, in general, so equations that are accepted [3]

da/dN is the crack growth in mm/cycle. So, The values of C and N can vary due to heat treatment and the condition of material, in general, so equations that are accepted [3]

For martensitic steels, this is:

Like, For ferrite-pearlite steels:

Like, For ferrite-pearlite steels:

And for aluminum [4]:

And for aluminum [4]:

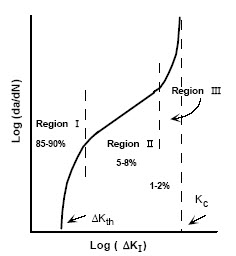

An example of a crack growth rate curve is shown in Figure 1 [5].

An example of a crack growth rate curve is shown in Figure 1 [5].

These basic equations can be used to calculate fatigue growth from some basic flaw size a to the critical flaw size ac, where catastrophic crack propagation can occur. So, The first thing that is needed is an understanding and relationship between the stress intensity factor, K

Fatigue 4.7 Crack Free Download 2022

Two well-known examples are:

- (i)

Crack growth in sheet material where the crack is growing through the full thickness of the material. So, An obvious example is fatigue growth in aircraft skin structures.

- (ii)

A second example is the growth of part through cracks, see Figure 5.3 where a corner crack or a surface crack starts at a hole. Part-through cracks also occur as surface cracks in welded structures at the toe of a weld. In the same way, In many practical cases, part through cracks is associate with massive components and thick plate structures.

Keywords

Fatigue Stress Intensity Factor Crack Length Crack Growth Rate Fatigue Growth

Fatigue Crack

- First of all Download From our website

- So, After this installation it

- Wait for the Complete process

- When it Done

- Like, Use it

- Enjoy it!